Horizontal Milling Machines

Manufacturing-type

•Cutter height is controlled by vertical movement of headstock

2. Special-type

• Designed for specific milling operations

3. Knee-and-column-type

• Relationship between cutter height and work controlled by vertical movement of table.

Manufacturing-Type

Used primarily for quantity production of identical parts •Distinctive features

•Automatic cycle of cutter and work approach

•Rapid movement during non-cutting cycle

•Automatic spindle stop.

Manufacturing-Type

Two common types

•Plain manufacturing type

•Small plain automatic knee and column type.

Plain Manufacturing Type Milling Machine

Special-Type Machines

•Designed for individual milling operations. •Used for only one particular type of job.

•Completely automatic

•Employed when hundreds or thousands of similar pieces are to be machined.

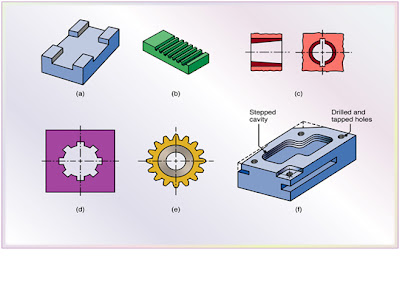

Machining Centers

•Capable of handling wide variety of work all in one setup.

•Straight and contour milling, drilling, reaming, tapping, and boring

Capable of high production rates while still maintaining high degree of accuracy.

•Rugged construction, reliable controls

•Anti-backlash ball screws.

Knee-and-Column-Type

Milling Machines

Machines in this class fall into three categories: •Plain horizontal milling machine.

•Universal horizontal milling machines.

•Vertical milling machines.

Universal Horizontal

Milling Machines

• Difference from plain horizontal machine is addition of table swivel housing.

• Located between table and saddle.

• Permits table to be swiveled 45º in either direction in a horizontal plane.

• Used for milling of helical grooves in twist drills, milling cutters, and gears.