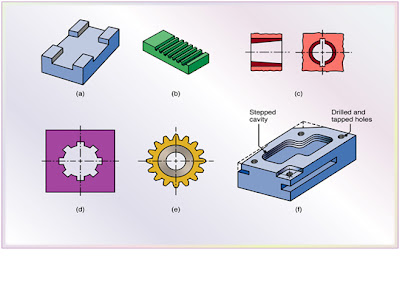

Machining Processes Used to Produce

Various Shapes: Milling, Broaching, Sawing, and Filing; Gear Manufacturing .

Parts Made with Machining Processes

Milling Cutters and Milling Operations

Figure 24.2 Some basic types of milling cutters and milling operations. (a) Peripheral milling.

(b) Face milling. (c)

End milling. (d)

Ball-end mill with index able coated-carbide inserts machining a cavity in a die block.

(e) Milling a sculptured surface with an end mill, using a five-axis numerical control machine. Source:

(d) Courtesy of Iscar. (e) Courtesy of The Ingersoll Milling Machine Co.

Milling Operations

Figure 24.3 (a) Schematic illustration of conventional milling and climb milling. (b) lab-milling operation showing depth-of-cut, d; feed per tooth, f; chip depth-of-cut, tc; and workpiece speed, v.

(c) Schematic illustration of cutter travel distance, lc, to reach full depth-of-cut.

Face-Milling OperationFigure 24.4 Face-milling operation showing (a) action of an insert in face milling; (b) climb milling; (c) conventional milling; (d) dimensions in face milling. The width of cut, w, is not necessarily the same as the cutter radius.

Summary of Peripheral Milling Parameters and Formulas

Usefull post! very nice design you show, This blog is very helpfull for me or public. I hope to see more quality design you show in next blog.keep writing up.

ReplyDeleteCheck here

Visit here

Additional info